You can’t manage what you can’t measure: Managing waste and recovering resources on mines and infrastructure projects

The Critical Input team recently undertook a wall-to-wall stocktake at a mine site as part of our Materials Management Review (MMR) process.

Our Materials Management Review (MMR) helps clients realise value from already purchased materials, such as spare, maintenance and inventory items, that are unknown, under-utilised, or obsolete. The process includes material identification, commercialisation or recycling options, warehouse practices and procedural amendments. So, not only does it save space, monetise waste, but it’s great for sustainability goals too.

There’s so many reasons to outsource this type of work. Firstly, it’s a massive job. We basically send in a dedicated team to Marie Kondo your work site. Just as sheds and cupboards at home can harbour junk and clutter, so too can workplaces. Add the fact that people move from job to job and different roles within the one company, and it’s easy to understand how sorting out excess pipes, equipment and other materials becomes “not my job” within a busy workplace.

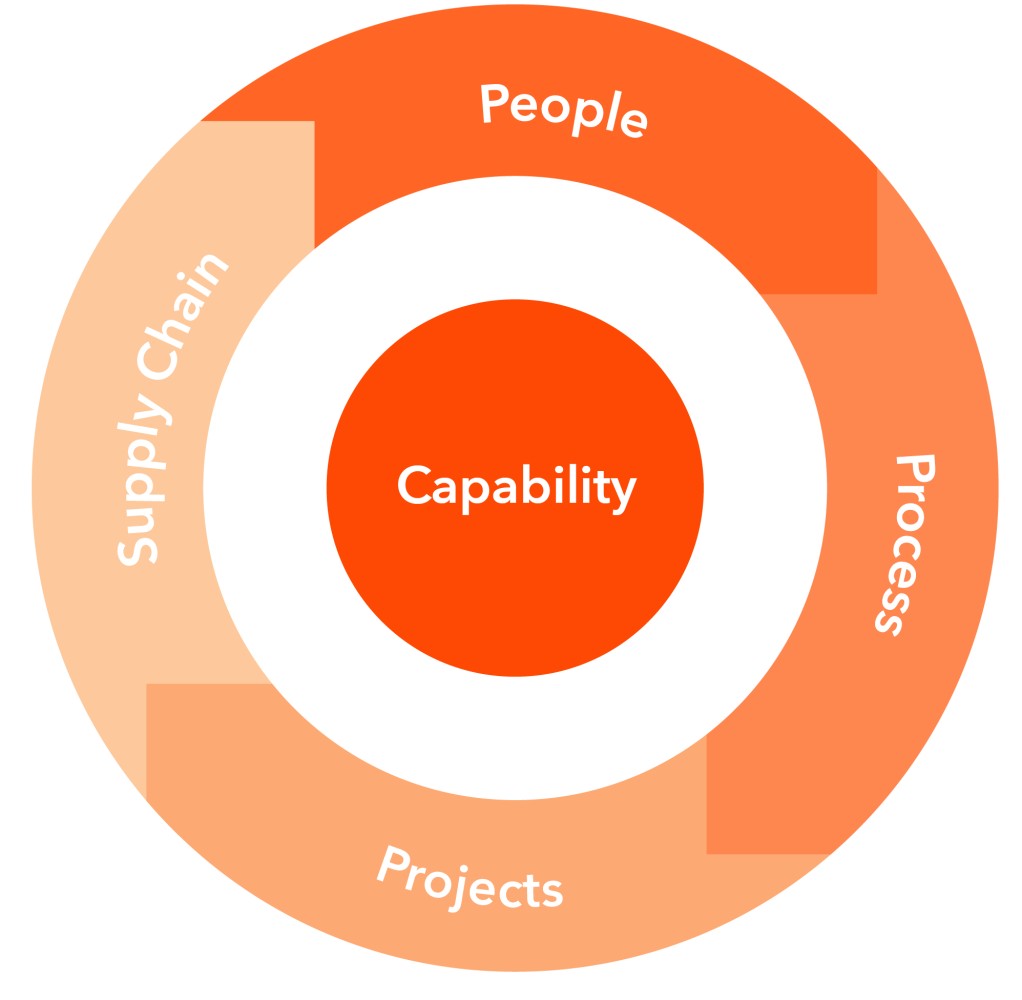

Supply chain waste triggers a multitude of trickle down costs – economic, aesthetic, environmental and efficiency costs. The common denominator behind corporate or industrial waste is a lack of process. Process provides the scaffolding and discipline to manage what an organisation has and what it needs before it acquires more. Industrial waste can lead to millions of dollars spent on goods that sit in warehouses or take up space at job sites, duplicated and forgotten.

Supply chain waste triggers a multitude of trickle down costs – economic, aesthetic, environmental and efficiency costs. The common denominator behind corporate or industrial waste is a lack of process. Process provides the scaffolding and discipline to manage what an organisation has and what it needs before it acquires more. Industrial waste can lead to millions of dollars spent on goods that sit in warehouses or take up space at job sites, duplicated and forgotten.

At Critical Input, we have seen sites where the contents of boxes, pallets and containers are unused and depreciating in value.

A few years ago, we took on a project with a mining company that hadn’t counted its underground stores for about 20 years.

We found $3 million worth of saleable goods untouched for nearly 20 years. Why? Inventory wasn’t managed. When restructure occurred or people changed jobs, roles and responsibilities relating to the goods weren’t communicated.

Essentially, they didn’t have the processes in place to ensure the efficient management of its supply chain, inventory.

Our MMR is a two-phased approach:

Phase One (duration: two weeks): Critical Input’s Material Management Review Phase One review provides an initial snapshot of your organisation’s physical management of both inventory and non-inventory items across a sample of the various storage locations. This review provides recommendations for additional material identification processes, commercialisation or recycling options, warehouse practices and procedural amendments.

Optional Phase Two: Staged or full review of all storage locations and the implementation of the agreed recommendations overseen by a single Critical Input Senior Consultant. Critical Input conducts Phase Two collaboratively with your team to ensure the organisation retains decision points, knowledge and expertise.

Why do it a Materials Management Review?

You can’t manage what you don’t measure. Multiple storage locations between different work divisions, geographical spread, non-inventory items purchased for completed projects and capitalised components for decommissioned assets are examples of corporate wastage and missed commercial or sustainability opportunities.

Need to Marie Kondo your site during 2023? Get in touch.