Pivot before panic

Have you done a supply chain health check?

According to supply chain expert Tim Griffiths, every organisation will have a base understanding of where their supply chain risks lie, but when you throw in a significant unknown like COVID-19, it’s prudent to consider “what ifs”.

Tim, who is the Managing Director of business consultancy Critical Input, said it’s not about being negative, but more about pre-empting various scenarios while there is time to pivot, rather than panic.

The ‘what if’ exercise

He provides a hypothetical scenario to illustrate.

“What if you’re an Australian brewery and your packaging is sourced from China and that particular glass bottle is not available due to impacts of COVID-19,” Tim queried.

“How much stock do you have in your inventory? When will you run out? Do you need to use this lead time to investigate an alternative supplier? Would this mean you need to re-design and re-print labelling to fit a slightly differently shaped bottle? Would you need new cartons in which to transport them? Would the new bottle be compatible with your production line?

“And what if, you source a particular yeast from an Australian supplier and that supplier’s workforce gets struck down by the virus – what options are available? What if there are no alternatives, what are the ramifications on halting production for a period of time? Who do you need to keep updated? Do you need to contact retailers to ensure you’re not contractually penalised for failure to supply?”

Under pressure

The pressure on businesses to provide fast and reliable services is high, as is the need to predict, assess and mitigate the risk of supply chain disruptions.

“Normal operating business-as-usual activities for any organisation include an awareness of supply chain elements, which of those are critical inputs and a basic risk assessment of those components, but we need to factor in the unexpected,” Tim said.

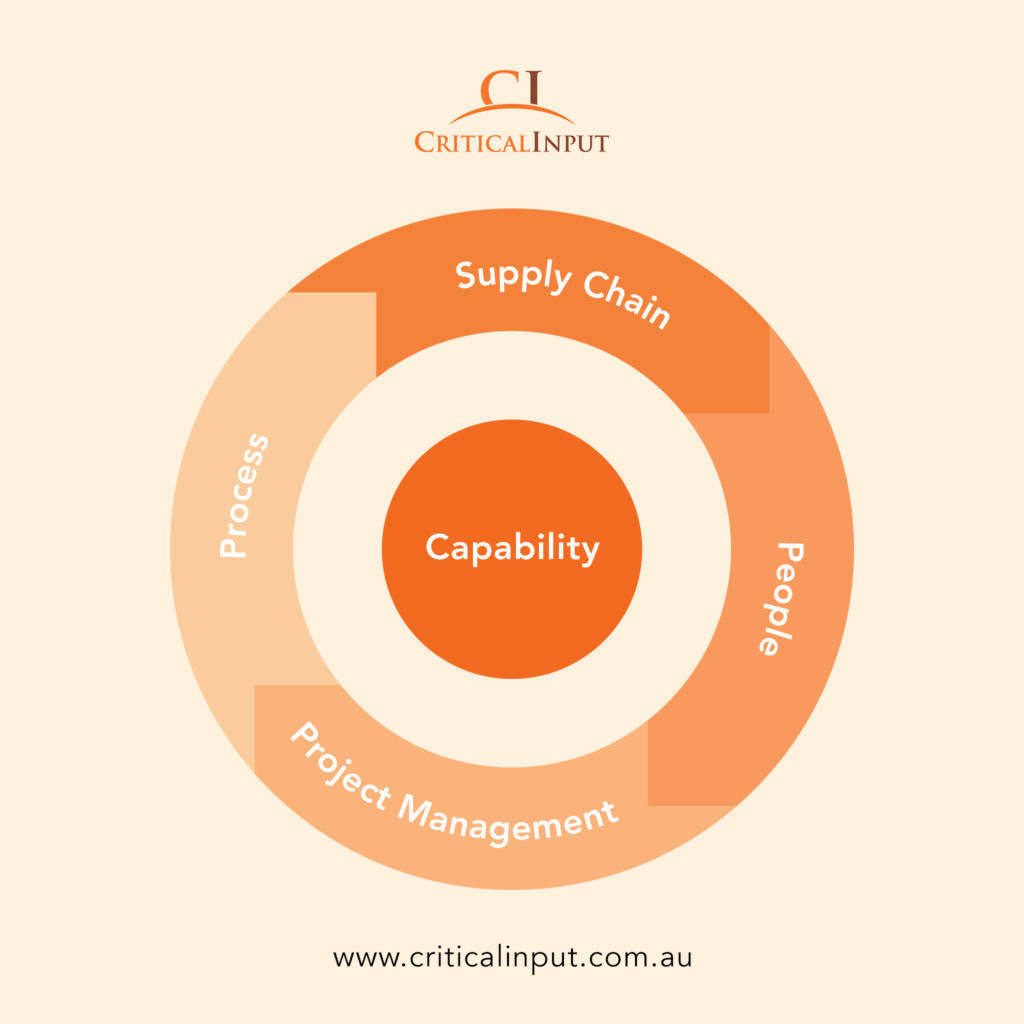

“Critical inputs vary for each organisation, but they could be electricity, raw materials, packaging, water, logistics or people.”

When the going gets tough

Given the impact of COVID-19 on supply chains, the workforce, the operations of government, and the economy as a whole, the casualties will inevitably include businesses as well as individuals.

The knock-on effect of COVID-19 is already impacting organisations both big and small across all industries and wreaking havoc on supplies of everything from toilet paper and face masks to specialised components and electrical goods.

While the full impact has yet to be felt, there are reported cases of businesses citing COVID-19 as the cause of, or a significant contributing factor to, financial and supply issues.

“While imagining worst case scenarios might not seem like a particularly fun exercise, rationally planning ahead and making hard decisions will increase your resilience to events outside your control,” Tim said.

“Ideally, you’ll never have to visit plan b, c or d, but it’s still important that you consider these supply chain issues in advance.”

Critical Input offers supply chain mapping and risk assessments for organisations needing guidance.

Safety first always

The preservation of life is always the highest priority, so while it’s important to plan ahead, the most important factor is the safety and wellbeing of people.

“During times of uncertainty, it’s normal to go through various stress responses, but it’s important to look out for one another, show care, consideration and a community spirit,” Tim said.

“There may be cases where the risk of doing business is too high and it’s a matter of taking the financial hit.

“Our collective humanity is part of the fabric of Australian culture and contributes to long-term resilience.”