Program Logistics Studies: The Aussie reality check for major projects

Program Logistics Studies: The Aussie reality check for major projects

Most logistics planning on big projects is really site logistics – laydown, cranage, gates, traffic controllers, and a mud-map that gets rewritten after the first truck meets the first roundabout.

It’s necessary, but it’s not enough.

In Australia, the schedule killers usually sit outside the fence, on public roads, bridges, rail corridors, ports, and in community and approvals pathways that don’t care what your contract says.

If your program relies on heavy, oversized, high-value equipment (think transformers, switchgear, pumps, pressure pipe, treatment process packages, rotating plant), you need a Program Logistics Study early.

And you need it tied into program controls, procurement and approvals for streamlined success.

Why this matters in Australia?

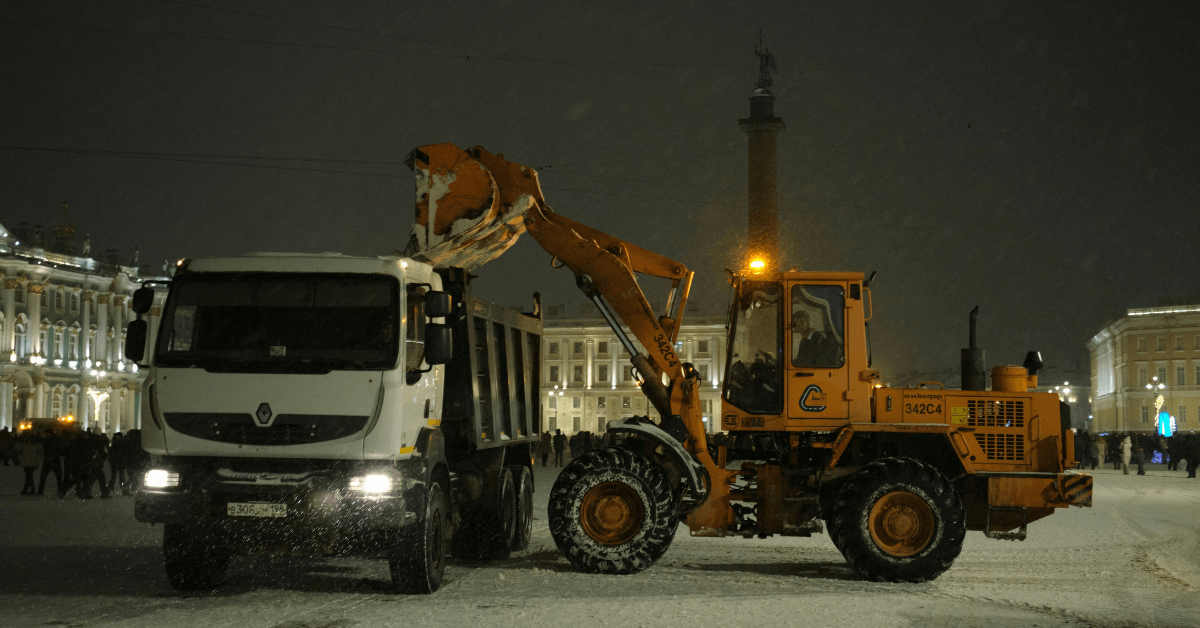

Long distances and thin corridors – a lot of work is regional. You’re dealing with:

- Long haul routes through towns, floodways’ and single-lane bridges

- Limited alternatives (one road in, and one road out)

- Seasonal closures and weather events that make float disappear fast

Bridge and road limitations are real (and common) – the big stuff is an infrastructure problem, not just a truck problem:

- Bridge ratings and axle loads

- Swept paths through intersections/roundabouts

- Overhead clearances and utilities

- Pavement capacity (especially on regional roads)

You don’t want to discover the constraint after the OEM has built the item and it’s sitting at a port accruing storage

OSOM access is a regulated pathway, not admin – oversize moves require planning across:

- NVHR access decisions (where applicable)

- State/territory road managers

- Councils, police escorts, traffic control approvals

- Route assessments and conditions that can change

It’s a workflow with lead times and it belongs in the master schedule.

Rail and ports are capacity systems (with windows, not wishes) – if you’re using rail or ports, you’re competing with:

- Planned works, possession windows, curfews

- Limited cranage/laydown capacity

- Quarantine, inspection, handling constraints

- Industrial relations and access rules

Community impact is not soft, it’s permission to operation – in Australia, abnormal load convoys and high-frequency haulage hit:

- School zones, local business access, emergency services routes

- Noise restrictions (night moves), road closures, detours

- Stakeholder tolerance (and therefore, political tolerance)

If you don’t manage it in logistics, you’ll manage it later, under pressure.

What a Program Logistics Study should cover (tighter + practical)

A proper study is a deliverability proof, not a report. At minimum it should produce these eight outputs:

1. Critical Movements Register

What is moving (dimensions/weights/handling/storage), when it must move, risk rating, and who owns it.

2. Mode & Corridor Strategy (road/rail/sea/intermodal)

Preferred corridors + alternates, with constraints mapped and verified.

3. Route Surveys and Engineering Checks

Bridge assessments, swept paths, clearances, holding yards, turning points, and re-validation triggers.

4. Access & Permits Plan (OSOM)

Approval pathways, lead times, dependencies, escorts, traffic control requirements, conditions.

5. Infrastructure Upgrade Plan

Temporary/permanent works required (bridge strengthening, intersection mods, pavement upgrades), funding and delivery responsibility.

6. Port/Rail Interface Plan (if relevant)

Handling, cranage, laydown, quarantine, possession windows, bookings, and contingencies.

7. Community & Stakeholder Impact Plan

Notifications, mitigation measures, school/emergency services interfaces, local access commitments.

8. Logistics Governance and Reporting

RACI, a permits/register, a logistics risk register, and a logistics readiness dashboard that links to schedule risk.

The biggest Aussie trap? Logistics not integrated to procurement + schedule

A recurring failure pattern is:

- Procurement commits to delivery dates,

- engineering finalises weights/dimensions late,

- logistics starts “after award,”

- route constraints surface,

- approvals and/or upgrades take months,

- the program pays in delay + acceleration + claims.

It’s all avoidable if logistics is treated as a program control discipline from day one.

If you want certainty, don’t ask “Do we have a logistics plan?”

Instead, here’s what to insist on:

- Has the route been surveyed and verified for each critical item?

- Do we have OSOM access decisions and permit lead times in the schedule?

- Are required road/bridge upgrades defined, funded, and sequenced?

- Do we have community/stakeholder impacts mapped and managed?

- Is logistics readiness reported like cost and schedule, weekly, with actions?

If the answer is “we’re working on it,” you’re already too late.

Program Logistics Studies: proving deliverability early (before it all falls apart)

In Australia, most program logistics is a network problem – roads, bridges, rail, ports, and people – not a site problem. A Program Logistics Study is how you prove deliverability early, protect the critical path, and stop simple transport turning into a six-month surprise.

If you’re interested in exploring the benefits of Critical Input’s Program Logistics Study, get in contact with us today.